Suspension Setup for Rocky Terrain: The Utah Dialing Guide

Rocky terrain demands specific suspension settings. This comprehensive guide breaks down exactly how to set up your WP XACT or XPLOR suspension for Utah's punishing rocks.

After 15 years of dialing suspension for Utah’s rocky terrain, one truth remains: the difference between fighting your bike and flowing over rocks is proper suspension setup. This guide distills thousands of hours of testing into actionable settings you can apply today.

The Rocky Terrain Challenge

Why Rocks Are Different

Rocky terrain presents unique suspension challenges:

- Square-edge hits: Instantaneous force spikes

- Deflection: Front wheel bouncing off line

- Traction loss: Suspension can’t follow terrain

- Rider fatigue: Fighting stiff suspension

- Inconsistent feedback: Can’t predict bike behavior

Standard suspension settings optimized for flow trails or sand will punish you on rocks. Here’s how to transform your bike’s capability.

Foundation: Spring Rate Selection

The Most Critical Decision

Before touching clickers, spring rate must be correct. Wrong springs = impossible to dial.

Spring Rate Quick Reference (WP XACT):

| Rider Weight | Fork Spring | Shock Spring | Notes |

|---|---|---|---|

| 140-160 lbs | 4.2 N/mm | 42-45 N/mm | Light riders need precision |

| 160-180 lbs | 4.4 N/mm | 45-48 N/mm | Most common range |

| 180-200 lbs | 4.6 N/mm | 48-52 N/mm | Standard “big guy” setup |

| 200-220 lbs | 4.8 N/mm | 52-54 N/mm | Consider custom valving |

| 220+ lbs | 5.0 N/mm | 54-57 N/mm | Definitely need revalve |

Rocky Terrain Adjustment: Go one rate stiffer than sand/flow recommendations. Rocks require more support.

Setting Sag: The Rocky Reality

Traditional sag numbers don’t apply to technical terrain:

Target Sag for Rocks:

- Static sag: 100-105mm (not 105-110mm)

- Race sag: 95-100mm (measured with gear)

- Free sag: 30-35mm (critical indicator)

Why Less Sag?

- More available travel for big hits

- Better platform for technical moves

- Reduced dive under braking

- Improved front/rear balance

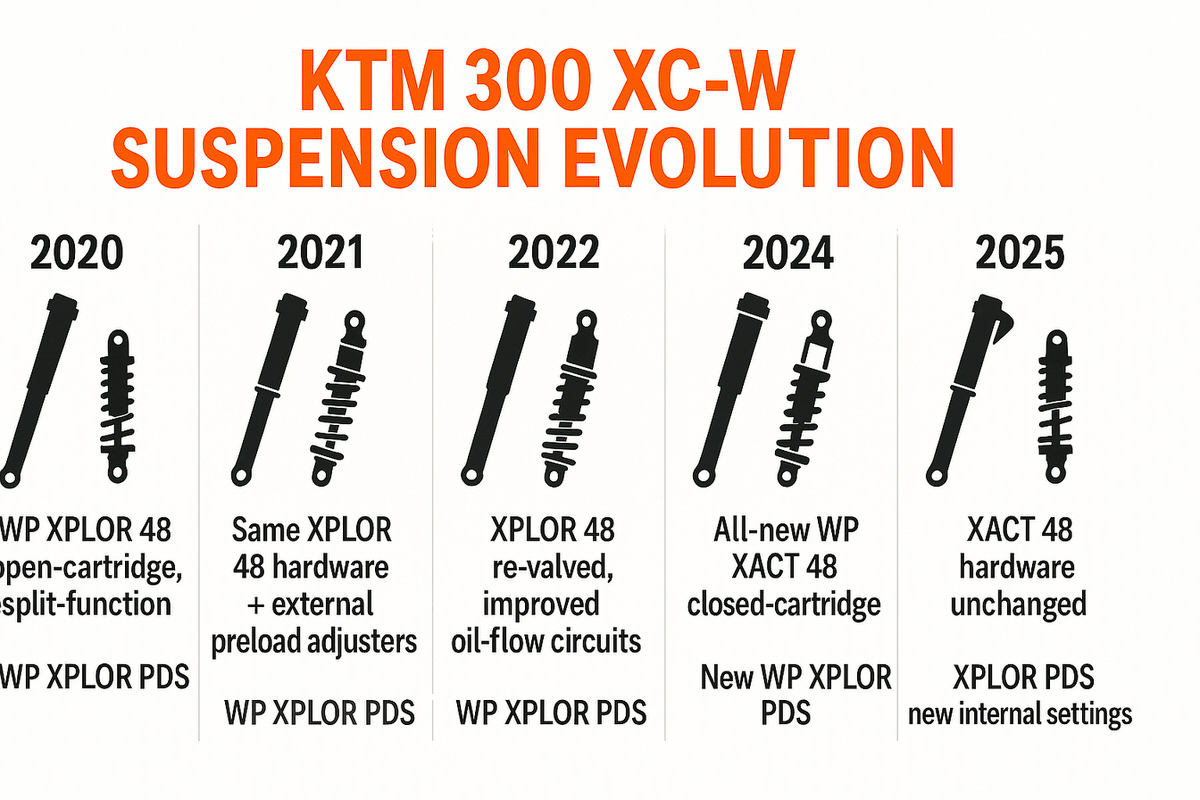

KTM 300 XC-W Suspension Evolution: Know Your Hardware

Understanding which suspension generation you’re working with is crucial for proper setup. The last 5 years have seen significant changes:

2020-2023 (XPLOR Era): Open-cartridge fork gradually refined—first with preload adjusters, then firmer valving.

2024-2025 (XACT Era): Closed-cartridge fork, tool-free clickers, and a redesigned shock. 2025 tweaks the shock’s internals but leaves hardware intact.

Complete Evolution Table

| Model Year | Front Fork | Rear Shock | What Changed vs. Previous Year |

|---|---|---|---|

| 2020 | WP XPLOR 48 mm open-cartridge, split-function • New calibrated mid-valve piston • New fork caps & adjusters |

WP XPLOR PDS with second damping piston & reshaped sealing cup | Entire chassis/suspension overhauled for the new generation; more bottom-out resistance and higher ride height |

| 2021 | Same XPLOR 48 hardware + external preload adjusters on both fork legs | PDS shock carries over | Riders can set sag without tools; no internal valving change |

| 2022 | XPLOR 48 re-valved (firmer high-speed damping) and improved oil-flow circuits | Shock re-shimmed for a “sportier, more consistent feel” | Suspension feels more planted and resists fade on long stints |

| 2023 | XPLOR 48 continues, fully adjustable | PDS still standard | Only minor setting refinements; hardware unchanged |

| 2024 | All-new WP XACT 48 closed-cartridge spring fork • New mid-valve & 68 mm hydro-stop • Tool-free clickers (top & bottom) |

New shorter WP XPLOR PDS shock with hand-adjustable high- & low-speed compression and rebound | Biggest leap since 2020: new frame geometry, lighter shock (-380 g) and full tool-free adjustability |

| 2025 | XACT 48 hardware unchanged | XPLOR PDS gets new internal settings for better pressure balance and reduced cavitation | Refinement year—focus on plushness and durability, plus revised chain-guide hardware |

What This Means for Your Setup

XPLOR Era (2020-2023):

- Open-cartridge design more sensitive to oil level changes

- Requires more frequent service intervals in rocky terrain

- Limited adjustment range compared to XACT

- Works best with aftermarket preload adjusters (if pre-2021)

XACT Era (2024+):

- Closed-cartridge maintains consistency longer

- Tool-free adjustments allow trailside tuning

- Wider effective adjustment range

- Better suited to extreme rocky terrain out of the box

Fork Setup: Making It Work

WP XACT 48 Settings

Baseline Rocky Terrain Settings:

- Compression: 10-12 clicks from closed

- Rebound: 14-16 clicks from closed

- Air chamber: 130-140mm (10mm less than standard)

- Oil level: 290cc per leg (+10cc)

- Fork height: 5mm above clamp

Understanding Compression

The Rocky Paradox: You need LESS compression for rocks, not more.

Why? Suspension must react instantly to square edges. Too much compression = deflection.

Progressive Adjustment:

- Start at 15 clicks out

- Find rocky test section

- Reduce 2 clicks at a time

- Stop when control degrades

Signs of Too Little Compression:

- Diving excessively on braking

- Wallowing in corners

- Using full travel constantly

Signs of Too Much Compression:

- Deflecting off rocks

- Arms pumping quickly

- Harsh feel over small bumps

Rebound: The Forgotten Setting

Rebound controls how fast fork extends after compression. Critical for rocks.

Fast Rebound (More Clicks Out):

- Better for successive hits

- Prevents packing down

- Maintains ride height

Slow Rebound (Fewer Clicks Out):

- More control on big hits

- Reduces “pogo” effect

- Better for isolated obstacles

Rocky Terrain Sweet Spot: 14-16 clicks provides best compromise.

Shock Setup: The Power Center

WP XACT Shock Specifics

Baseline Rocky Settings:

- High-speed compression: 1.5-1.75 turns out

- Low-speed compression: 14-16 clicks out

- Rebound: 14-16 clicks out

- Preload: 5-7mm

High-Speed vs Low-Speed

Understanding the difference transforms your setup:

High-Speed Compression:

- Controls big hits, g-outs

- Prevents bottoming

- 1/4 turn = major change

Low-Speed Compression:

- Body movement, brake dive

- Platform feel

- 2-3 clicks = noticeable

Rocky Reality: Open HS more than you think. Rocks create high shaft speeds.

PDS vs Linkage Differences

PDS (KTM XC-W) Characteristics:

- More progressive naturally

- Needs slower rebound

- Better for technical

- Less adjustment range

Linkage (Husqvarna TE) Benefits:

- More linear feel

- Wider adjustment range

- Better for mixed terrain

- Easier to tune

Setup Differences:

- PDS: Run 2-3 clicks slower rebound

- Linkage: Can run faster rebound

- PDS: Less preload needed

- Linkage: More preload acceptable

Location-Specific Settings

American Fork Canyon Setup

Terrain: Embedded rocks, roots, technical climbs

Fork:

- Compression: 10-11 clicks

- Rebound: 15-16 clicks

- Oil level: +15cc from stock

Shock:

- HS Comp: 1.75 turns out

- LS Comp: 15-16 clicks

- Rebound: 14-15 clicks

Why: Maximum compliance for constant rock impacts.

San Rafael Swell Setup

Terrain: Ledges, loose rocks, big hits

Fork:

- Compression: 12-14 clicks

- Rebound: 13-14 clicks (faster)

- Air chamber: 135mm

Shock:

- HS Comp: 1.25 turns out (firmer)

- LS Comp: 12-13 clicks

- Rebound: 15-16 clicks

Why: More support for G-outs, faster rebound for successive hits.

Moab Slickrock Setup

Terrain: Traction-dependent, steep angles

Fork:

- Compression: 13-14 clicks

- Rebound: 16-18 clicks (slower)

- Standard oil level

Shock:

- HS Comp: 1.5 turns (standard)

- LS Comp: 12-14 clicks

- Rebound: 16-18 clicks (slower)

Why: Slower rebound maintains traction on steep slickrock.

Advanced Tuning Techniques

Oil Level Magic

Fork oil level fine-tunes bottom resistance:

Stock: 280cc per leg Rocky +10cc: 290cc - more bottom resistance Rocky +20cc: 300cc - significant change

How to Adjust:

- Remove fork caps (bike secure)

- Compress fork fully

- Measure from top of tube

- Add/remove oil as needed

Air Chamber Tuning

Affects progression curve:

Larger Chamber (150-160mm):

- More linear feel

- Less bottom resistance

- Better small bump

Smaller Chamber (130-140mm):

- More progressive

- Better bottom resistance

- Sacrifices initial comfort

The Bleed Trick

Bleeding excess pressure improves compliance:

- Compress fork/shock fully

- Crack bleed screw briefly

- Release compression

- Repeat 2-3 times

Removes pressure build-up, improves action.

Common Problems and Solutions

Problem: Harsh Over Small Rocks

Diagnosis: Too much compression, wrong oil weight

Solution:

- Reduce compression 3-4 clicks

- Check oil level (may be too high)

- Ensure correct spring rate

- Consider lighter oil weight

Problem: Deflecting Off Rocks

Diagnosis: Over-damped, too stiff

Solution:

- Open compression significantly

- Speed up rebound 2 clicks

- Lower tire pressure 1-2 PSI

- Check rider position

Problem: Using Full Travel Constantly

Diagnosis: Under-sprung or under-damped

Solution:

- Increase spring rate

- Add high-speed compression

- Check sag (may be excessive)

- Add oil for bottom resistance

Problem: Arm Pump

Diagnosis: Fighting suspension, poor setup

Solution:

- Reduce overall compression

- Check bar position

- Relax grip (seriously)

- Consider softer springs

Testing Protocol

The Right Way to Test

Step 1: Find Representative Terrain

- Mix of rock sizes

- Some speed sections

- Technical challenges

- Consistent loop

Step 2: Baseline Run

- Note specific problems

- Mark harsh sections

- Time the loop

- Note fatigue points

Step 3: Make ONE Change

- Adjust 2-3 clicks only

- Front OR rear, not both

- Write down change

- Retest immediately

Step 4: Evaluate Honestly

- Better or worse?

- New problems created?

- Overall improvement?

- Fatigue difference?

Step 5: Refine

- Chase improvement direction

- Don’t over-adjust

- Know when to stop

- Document final settings

Maintenance for Rocky Terrain

Increased Wear Reality

Rocks accelerate suspension wear:

Service Intervals:

- Fork: Every 30-40 hours (not 50)

- Shock: Every 40-50 hours (not 100)

- Linkage: Every 20 hours

- Air filter: Every ride

Critical Inspection Points:

- Fork seal condition

- Shock shaft wear

- Linkage bearing play

- Spring condition

DIY Maintenance

After Every Rocky Ride:

- Clean fork stanchions thoroughly

- Check for oil weepage

- Cycle suspension feeling for notches

- Inspect dust wipers

Weekly:

- Check sag (springs settle)

- Verify clicker positions

- Clean and lube linkage

- Check mounting bolts

The Mental Component

Trust Your Setup

Confidence in suspension = faster riding. Period.

Building Trust:

- Make changes gradually

- Test thoroughly

- Commit to settings

- Stop second-guessing

When to Get Help

Consider Professional Help When:

- Stock settings aren’t close

- You’ve tried everything

- Bike feels dangerous

- Considering revalve

What Shops Provide:

- Custom valving

- Spring rate expertise

- Problem diagnosis

- Rider-specific setup

Final Wisdom

After years of testing, these truths emerge:

- Softer is usually faster on rocks

- Spring rate matters more than clickers

- Oil level changes are free horsepower

- Trust feel over numbers

- Every rider needs different settings

The “perfect” setup is the one that lets you ride without thinking about suspension. When you stop fighting your bike and start flowing over rocks, you’ve found it.

Ready to dial your suspension for Utah’s rocks? Our suspension service includes custom setup for your weight, speed, and favorite trails.

What suspension challenges do you face on rocky terrain? Share your setup discoveries below.

About Mountain Goat Sports

Professional motorcycle repair & suspension tuning for Utah hard enduro riders. Specializing in KTM, Husqvarna, and GasGas dirt bikes.

Related Articles

Red Trail Guide: San Rafael Swell's Technical Challenge

The Red Trail in the San Rafael Swell delivers one of Utah’s most rewarding technical single track experiences. This ...

The Ultimate Guide to Utah Hard Enduro Riding

Utah offers some of North America's most challenging hard enduro terrain. This comprehensive guide covers everything ...

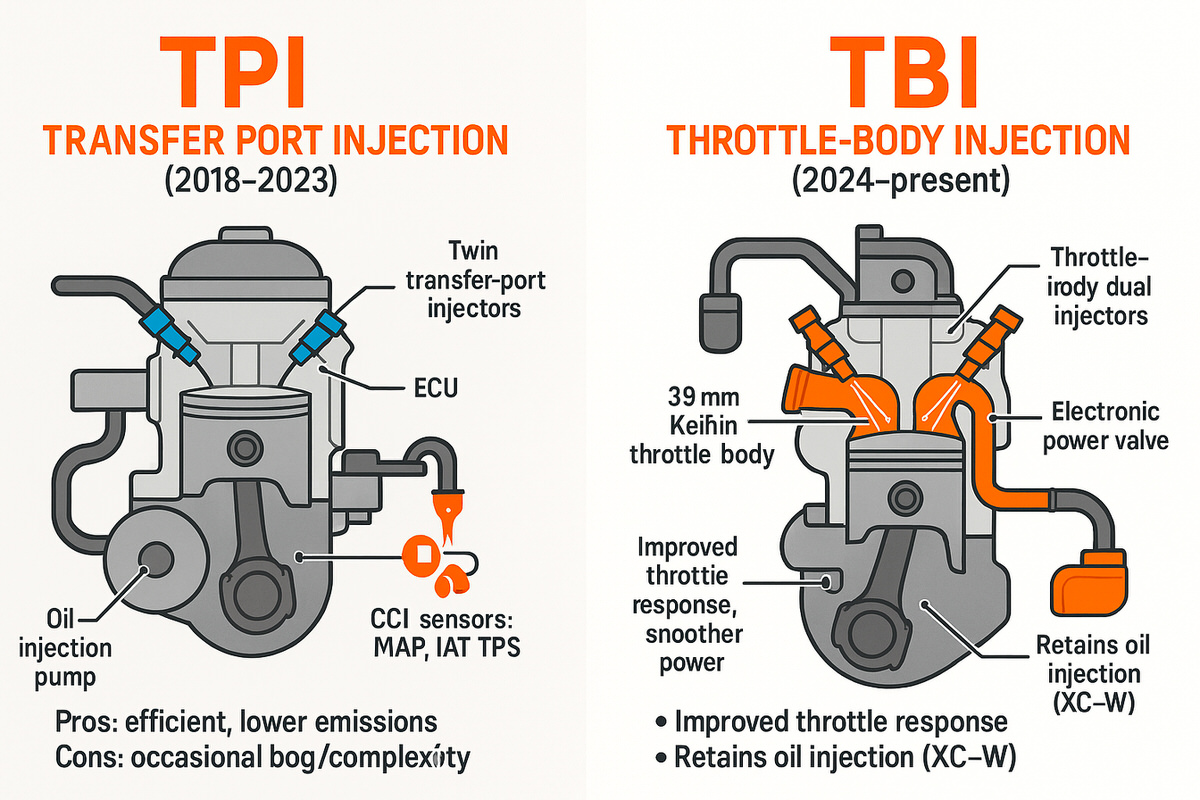

TBI vs TPI Explained: KTM's Fuel Injection Systems Decoded

KTM's shift from TPI to TBI has riders confused. This technical deep-dive explains both fuel injection systems, their...

Winter Riding in Warner Valley: Utah's Desert Escape

When northern Utah's trails are buried under snow, Warner Valley offers perfect riding conditions with 60-degree temp...

Need Service for Your Bike?

Our expert technicians are ready to help with all your motorcycle needs. From suspension tuning to engine rebuilds, we've got you covered.